Why Stability Testing Protocols Are Essential for Drug Development

Drug development is a meticulous, rigorous process where every phase is guided by regulatory standards to ensure safety, efficacy and quality. One of the most critical steps in this process is stability testing protocols. These protocols ensure the drug remains effective, safe and potent throughout its shelf life. With increasing scrutiny on the safety of pharmaceutical products, drug manufacturers cannot afford to overlook stability testing.

Here we’ll take a closer look at why stability testing protocols are vital to drug development. We will discuss their role in ensuring regulatory compliance, maintaining product quality, supporting clinical trials and much more.

Stability Testing Protocols

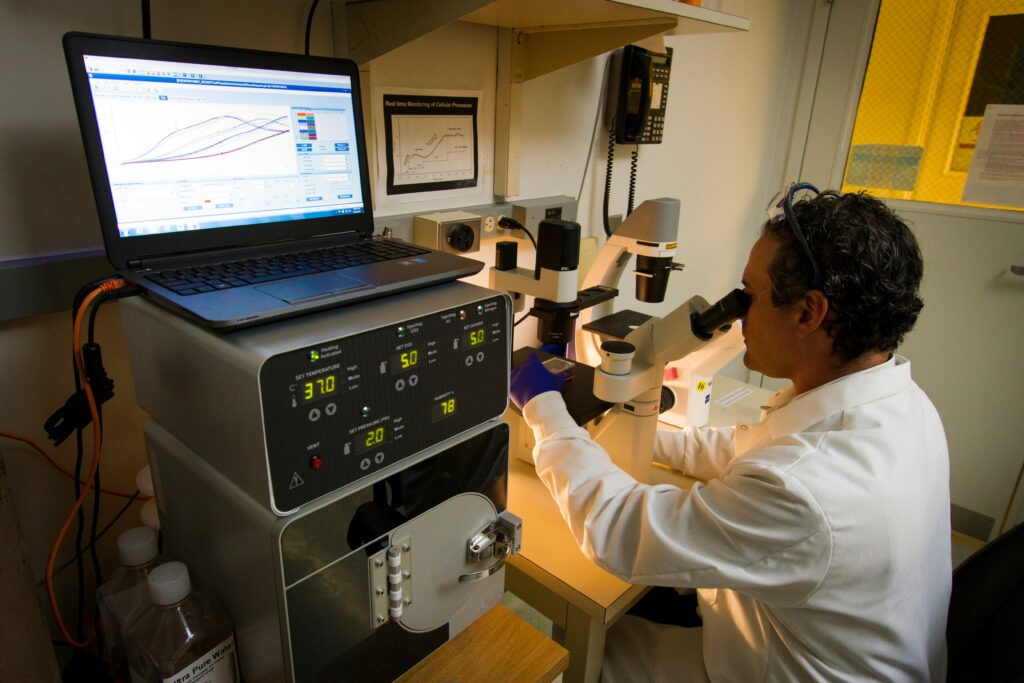

Stability testing protocols are fundamental to drug development. These protocols determine how a drug’s composition changes over time under various environmental conditions. It includes temperature, humidity and light exposure. Stability testing helps ensure that the drug remains safe and effective for the entire duration of its shelf life, which is especially important in maintaining the trust of patients and regulatory bodies alike.

What is Stability Testing?

Stability testing is the process of studying how different environmental factors affect the quality of a pharmaceutical product over time. By simulating real-life conditions that a drug might be subjected to, manufacturers can ensure it remains safe and effective throughout its intended shelf life.

Key Types of Stability Testing

Here are key stability testing protocols pharmaceutical companies use to ensure drug safety and effectiveness.

- Real-Time Stability Testing: This method simulates real-world conditions to measure how a drug product will behave in long-term storage. It is essential for determining a drug’s shelf life.

- Accelerated Stability Testing: This protocol exposes the drug to extreme conditions to fast-track the degradation process. It helps predict long-term stability in a shorter time frame.

- Forced Degradation Testing: This method deliberately stresses the drug to examine how it breaks down and its potential by-products.

These tests are mandatory for maintaining compliance with Good Manufacturing Practices (GMP) and securing approvals from regulatory agencies like the FDA, EMA and ICH.

Why Are Stability Testing Protocols So Important?

The importance of stability testing protocols cannot be overstated in the drug development process. These protocols serve several key functions:

Ensuring Safety and Efficacy

A drug is only valuable if it can safely deliver the intended therapeutic effect over time. Stability testing helps ensure the drug maintains its efficacy and safety throughout its shelf life. This is especially important for drugs that need to be taken over long periods, like chronic disease medications or vaccines.

Regulatory Compliance

Pharmaceutical companies must comply with regulatory requirements from bodies such as the FDA, EMA and ICH. Stability testing is required for drug approval and commercialisation. Incomplete or missing stability data can lead to costly delays or product rejections.

Patient Trust and Product Reliability

Patients and healthcare providers rely on the consistency of a drug’s formulation. Stability testing ensures that every batch of a drug product retains the same quality, potency and safety as the first. Without stability testing, a drug manufacturer risks undermining public trust, which can result in recalls, negative publicity or legal consequences.

Stability Testing and Regulatory Compliance

Below are the key ways stability testing supports regulatory compliance and ensures that pharmaceutical companies meet essential drug approval and market release standards.

Meeting FDA, EMA and ICH Guidelines

The FDA and EMA guidelines dictate the type of stability data required for drug approval. These agencies provide strict requirements for the conditions under which stability tests must be conducted. International Conference on Harmonisation (ICH) guidelines help standardise the stability testing process for global markets.

Good Manufacturing Practices (GMP)

GMP compliance requires manufacturers to test drug stability under controlled conditions. The FDA’s CGMP regulations ensure that the production, packaging and storage of drugs consistently meet standards to guarantee drug quality. A drug that fails stability testing could mean non-compliance with GMP, leading to potential penalties or product recalls.

The Role of Stability Testing in the Drug Development Lifecycle

Stability testing protocols play a crucial role throughout the entire drug development lifecycle.

Early Development Stages

In the early stages, stability testing protocols help formulation scientists identify the optimal conditions for drug development. Whether a drug is a small molecule or a biologic, stability testing helps refine the formulation and select packaging materials that best protect the drug.

Clinical Trials

As drugs progress into clinical trials, stability testing ensures the drug remains stable under varying conditions during storage and transportation. This is critical as drugs are often transported across regions with different environmental conditions.

Post-Market Surveillance

Even after a drug has been approved and released to the market, stability testing continues to monitor any potential changes in the drug’s composition. This ongoing testing helps identify issues with the drug’s long-term viability and ensures continuous product safety.

Stability Testing Protocols for Different Drug Forms

Stability testing is not a one-size-fits-all process. Different drug forms require unique protocols to ensure stability. Here’s a look at how stability testing differs based on the form of the drug:

Oral Dosage Forms

For tablets and capsules, real-time stability testing ensures that the active pharmaceutical ingredient (API) remains stable in the given excipient matrix and that the drug does not degrade into harmful by-products. This is especially important for extended-release formulations.

Injectable Drugs

Injectables require specialised testing, including testing for sterility and pH levels. Stability testing protocols must ensure the drug remains effective and free from contaminants even after storage and transport under various conditions.

Biologics and Biosimilars

Biologics require much more stringent testing due to their complex nature. Stability testing protocols for biologics need to account for changes in protein structure, degradation pathways and immunogenicity risks. Biologics are sensitive to slight temperature, humidity or light exposure variations.

Common Challenges in Stability Testing

Despite the clear importance of stability testing protocols, the process comes with its own set of challenges.

Environmental Factors

Fluctuations in temperature, humidity and light exposure can significantly affect the drug’s stability. Maintaining controlled testing environments is critical to ensuring accurate results. In some cases, simulating real-world storage conditions can be difficult.

Long Testing Periods

While accelerated stability testing can speed up the process, real-time stability testing takes longer to yield results. This prolonged testing period can be time-consuming and expensive, especially when developing high-volume drugs.

Expanding Regulatory Requirements

As global regulations evolve, so too must stability testing protocols. Keeping up with changing standards from the FDA, EMA and ICH requires continuous updates to testing protocols and the associated documentation.

Stability Testing’s Impact on Drug Market Success

Stability testing is not just about ensuring a drug remains potent and safe. It plays a pivotal role in the success of a pharmaceutical product in the market.

Minimising Risk

By rigorously testing stability, companies can reduce the risk of product recalls, which are costly and damaging to a brand’s reputation.

Ensuring Quality

Stability testing helps guarantee that the drug quality does not deteriorate, even after it has been on the market for extended periods.

Gaining a Competitive Advantage

Companies that invest in thorough stability testing protocols can differentiate themselves by consistently providing high-quality, reliable products. This gives them a competitive edge in the highly saturated pharmaceutical market.

The Role of Stability Testing in Post-Market Surveillance

Once a drug hits the market, its stability continues to be a priority. Stability testing protocols do not end with regulatory approval. They play an essential role in post-market surveillance, ensuring that drugs maintain their potency, safety and effectiveness over time. By continuously monitoring the drug’s stability in different environmental conditions, manufacturers can quickly detect any degradation or issues that might arise during distribution or storage.

- Monitoring shelf life: Ensures products retain their intended quality.

- Regulatory reporting: Helps comply with ongoing FDA or EMA requirements.

- Minimising market risks: Provides early detection of potential quality issues.

The Economic Impact of Stability Testing

Stability testing protocols impact a company’s bottom line by preventing costly mistakes and ensuring drugs remain viable throughout their shelf life. Validating a drug’s longevity helps streamline inventory, improve strategy and reduce recalls or reformulations, offering long-term savings.

- Reduced product recalls: Lower costs associated with returns or reformulation.

- Improved stock management: Predict product longevity for better resource allocation.

- Lower insurance premiums: Mitigate risks that could lead to higher insurance costs.

Investing in thorough stability testing protocols ensures a healthier financial return by preventing potential disruptions and enhancing market confidence.

Ready to Ensure the Quality of Your Drugs?

When it comes to stability testing protocols, the expertise of a trusted partner can make all the difference. Inglasia provides top-tier stability testing solutions that align with global regulatory standards, ensuring the long-term effectiveness and safety of your products.

Schedule a consultation with our experts today to learn how we can help safeguard your product’s quality and compliance.